Most industries have holes that are generally too small to see. These holes can be

thought of as ‘a lack something’, which can be a service, a functionality, a product

etc. Finding these holes can be the starting point for most companies and start-ups,

followed by the planning and development process to fill the hole.

This project was about one such hole.

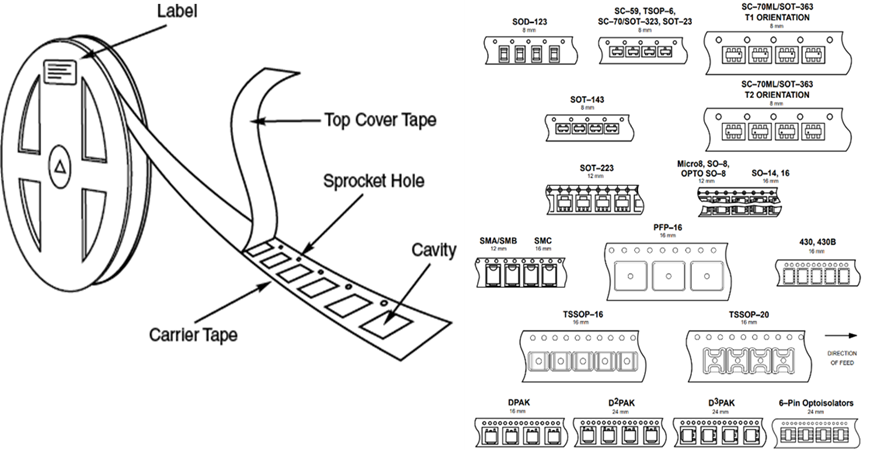

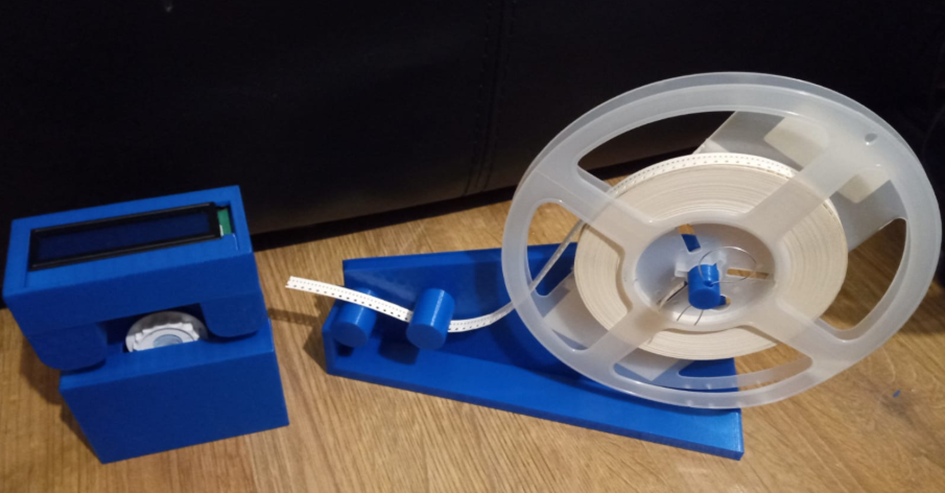

In the electronics industry, a common method of packaging the small SMD (Surface

Mount Device) components is via ‘Tape and Reeling’. The method involves the SMD

components to be placed in pockets embossed in a plastic carrier tape, which is then

wound around a disk-shaped reel.

The counting of these components, when shipping them out to buyers, does not have a

globally accepted, standard method. The research showed that different companies

used different methods for the counting the components, ranging from simply

measuring out the tape and taking an average, to the usage of bulky, expensive

machines.

One particular company, where the majority of Warehouse workers applied the ‘tape

measuring technique’, faced the problem of accuracy. They had received increasing

number of complaints from the buyers that the delivered number of components were

less than ordered.

The company decided to approach Leeds Beckett University to allow students to find a

solution to the problem. Under the supervision of Dr. Mark Judge, the problem was

assigned as a team project, with the team consisting of Lewis Riches, Hamza Khan and

Adam Casey.

Products available in the market, providing the same functionality, were studied

closely and the pros and cons of their usage were highlighted. It was noted that

most available products that provided high accuracy were expensive, bulky and, in

many cases, relatively less-simple to use.

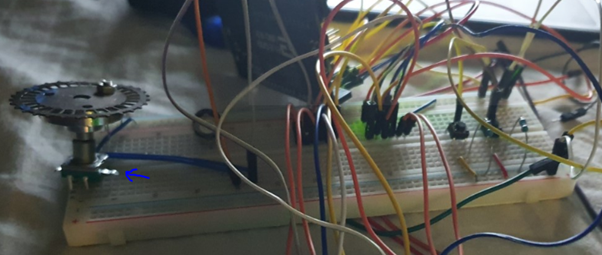

Different technologies (e.g., Rotary encoder, bar-code scanners, photo-interrupters

etc.) were studied, that had the potential to be used in the product to be

developed.

The development process was broken down into three parts: Counting mechanism, User

Input and Case Design.

The Counting mechanism was created using a teethed wheel connected with a rotary

encoder. An Arduino board was used as the brain behind counting, considering reverse

rotation etc. For the User Input, push buttons were used in the prototype, with room

for a keypad based alternative.

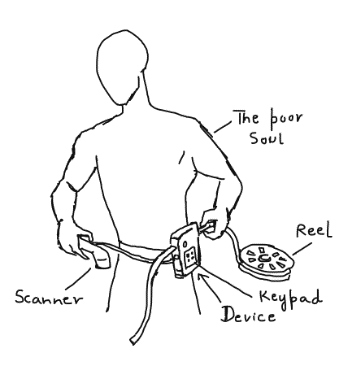

The case designed proved to be relatively more challenging since the product

demanded heavy focus on portability and ease-of-use.

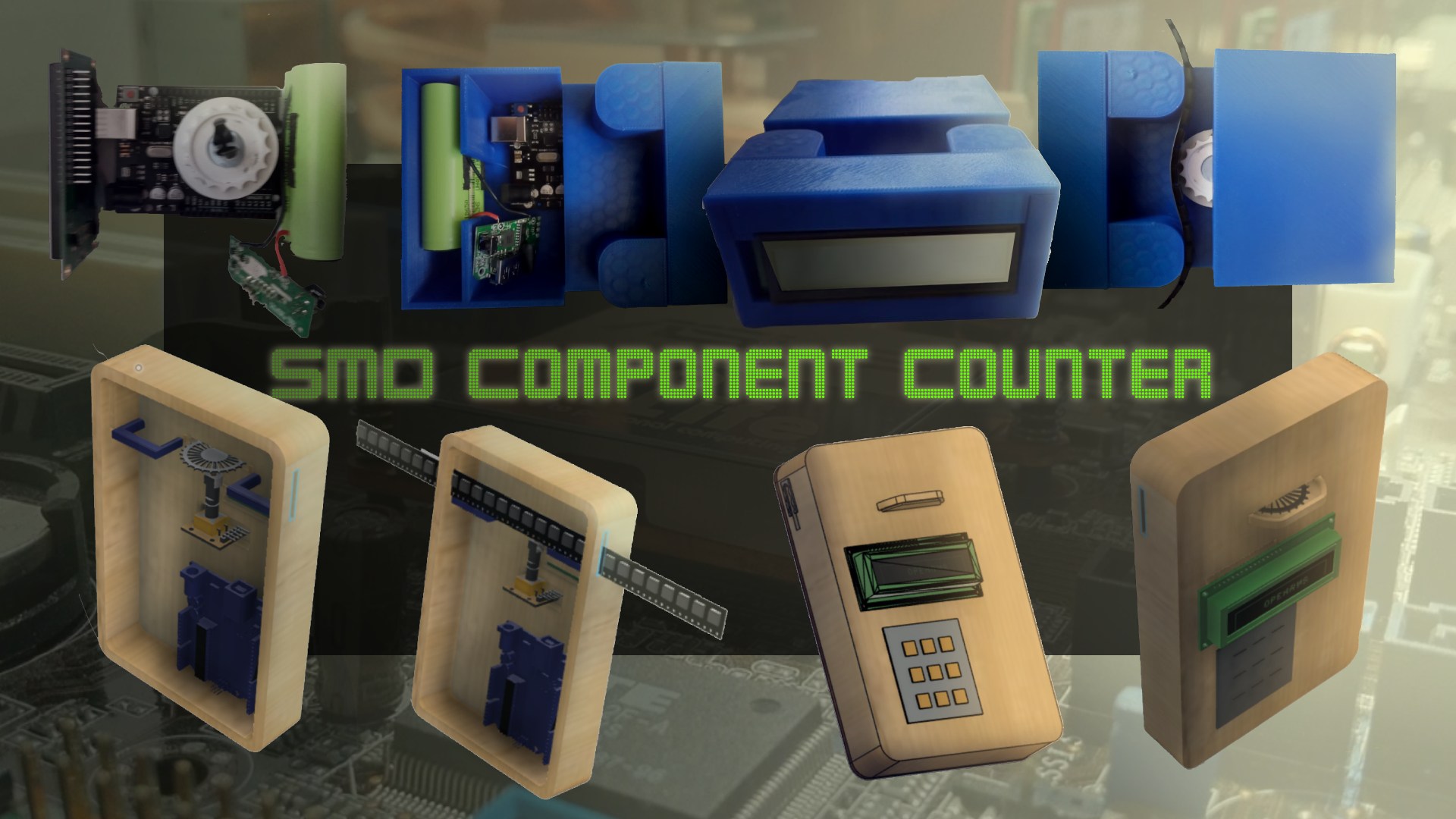

At this point, the team needed to improve the existing protype and put together its components into a final product. This was also the point when an unseen intruder, known to many as COVID-19, announced its existence. The team members were divided and had to work remotely.

This resulted in two different case designs:

A 3D-printed product:

A CAD-based design:

In conclusion, the product can be considered to be at a stage where, after heavy testing of the implemented prototype, the product can be taken to the manufacturing stage and introduced into the market.